Understanding Mold Building

Injection molding is a technique used to create complex plastic parts by injecting molten plastic into a mold, where the plastic is left to cool and solidify into the desired shape. The mold is a hollow metal block with multiple holes drilled into it for temperature control via heaters, oil, or hot water. Due to its efficiency, plastic injection molding is best suited for the mass production of products with complex shapes.

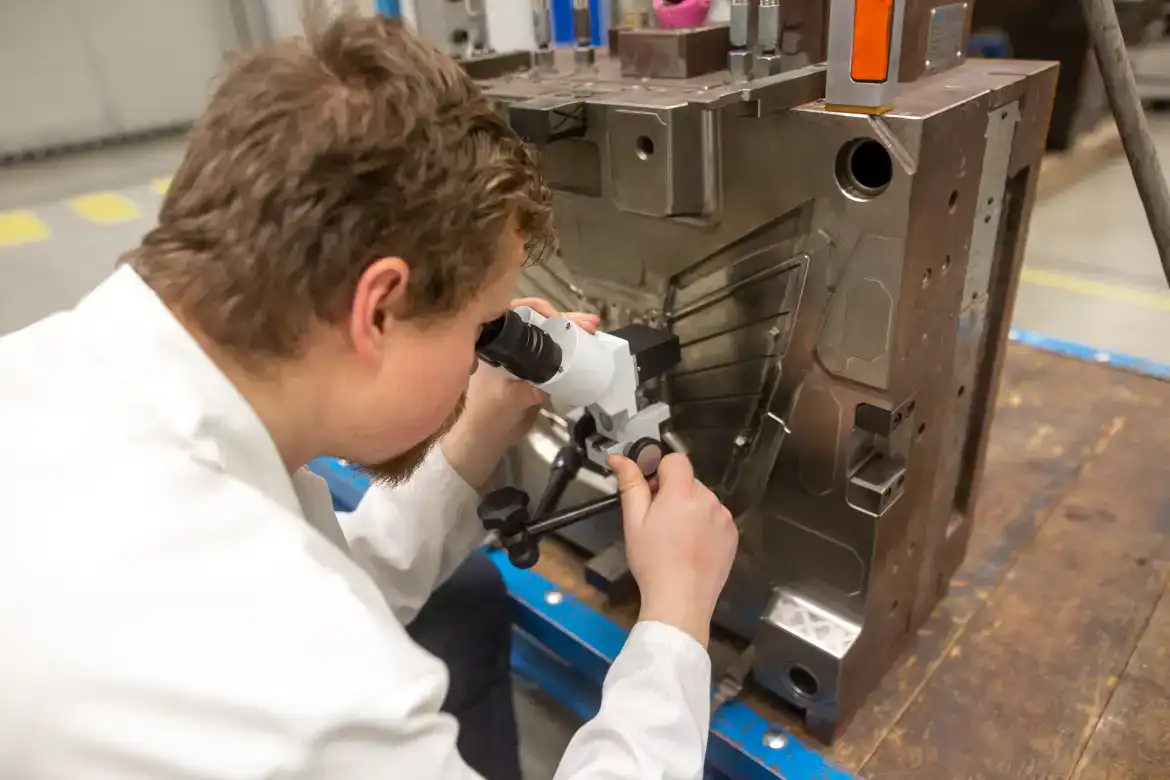

As a full-service mold manufacturer, Dramco Tool designs and builds molds to fit presses with up to a 1,300-ton capacity. We specialize in creating durable, cost-effective multi-shot injection molds, and thermoset molds for consumer product, automotive, and other industries. Our team also designs and builds compression molds for composite materials, including layup molds and resin transfer molds (RTM) for the aerospace and defense industry.

This comprehensive guide will discuss our mold-building process, the typical materials used, and the common challenges and solutions to multi-shot injection molding.

Design and Engineering Aspects

At Dramco Tool, our skilled and experienced mold builders work closely with customers to understand their unique requirements and turn them into cost-effective, long-lasting molds. Depending on the materials, geometry, and dimensions of your part, we can develop the ideal multi-shot mold that can produce parting lines that match throughout even high-volume production runs. We can also help you optimize your part designs for a successful outcome.

Our engineers and designers utilize the latest techniques and CAD software to develop optimized, precise designs for two-shot injection molding molds. Through trial runs and rapid prototyping, we ensure the final mold design meets the desired functionality and specifications of your application before proceeding to full-scale production.

Common Materials for Mold Building

Multi-shot injection molds are made of pre-hardened or hardened steel, beryllium-copper, and/or aluminum. Hardened steel molds are the most durable, offering the longest lifespan and greatest wear resistance for high-volume production runs.

To maximize the benefits of choosing a high-quality multi-shot mold, it is vital to select compatible materials capable of forming a molecular bond and meeting the functional requirements of the component. There are nearly unlimited variations in material selection and options for adjusting, blending, fine-tuning, and combining materials to create a final product.

Common materials used in multi-shot plastic injection molding include:

Acrylic

Acrylonitrile Butadiene Styrene (ABS)

Class A (color-matched)

Fiber Reinforced (SFR, LFR)

Glass Filled

Graining

Nylon

Polyethylene (LDPE, MDPE, HDPE)

Polypropylene (PP)

Polystyrene (PS)

Polyvinyl Chloride (PVC)

Talc Filled

Thermal Expanding Resin

Thermoplastic Polyolefin (TPO)

Thermoplastic Vulcanizate (TPV) - Santoprene®

Challenges and Solutions

1. Challenge: Material Flow

One of the most critical issues to address when molding large parts is the proper flow of material so that it fills the entire cavity of the mold. The molten plastic must travel a significant distance, creating the following potential risks:

- Pressure fluctuations

- Temperature variations

- Uneven flow rates

These issues can result in voids, inconsistent part properties, and incomplete filling.

Solution

- Select materials with favorable melt flow properties.

- Optimize the gate and runner design to facilitate smooth material flow.

- Utilize flow simulation software to predict and correct potential flow concerns.

2. Challenge: Cooling Large Parts

Cooling large parts can present a unique set of challenges. For instance, varying cooling rates can lead to distortion, internal stresses, and warping as the part solidifies.

The following cooling strategies are essential to maintaining the surface quality and dimensions of the part:

Ensure uniform cooling Implement conformal cooling and other advanced cooling techniques.

Adjust cooling system designs Adjusting the design of the cooling system can accommodate the geometry and larger size of the component.

Minimize dimensional changes Select materials with low shrinkage rates to minimize dimensional changes post-molding.

Solution

- Select materials with favorable melt flow properties.

- Optimize the gate and runner design to facilitate smooth material flow.

- Utilize flow simulation software to predict and correct potential flow concerns.

3. Challenge: Clamping Force Management

Large parts must have precise clamping force management to offset the high pressures exerted during the injection molding process. Inadequate clamping force can compromise part quality, lead to material leakage, and cause mold opening.

Solution

Here’s how to address this unique challenge:

- Optimize clamping force Make calculations based on the specific material properties, injection pressures, and part geometry to optimize the clamping force.

- Maintain consistent clamping force Incorporate real-time monitoring systems during the injection molding process to maintain consistent clamping force.

4. Challenge: Higher Injection Pressures

Higher injection pressures are often required to fill in larger parts and ensure proper material flow. However, properly managing these pressures while maintaining the quality of the part and safeguarding the integrity of the mold is often difficult to achieve.

Solution

- Consult material suppliers to choose polymers that can accommodate high injection pressures. Also fine-tune injection molding mold profiles to strike a proper balance between material flow and pressure.

5. Challenge: Increased Part Size

Larger parts pose a significant risk of defects, variations in material properties, and internal stresses. These challenges can impact the long-term durability and structural integrity of the components.

Solution

- Conduct comprehensive stress analyses to identify weak points, addressing them in the design phase. Choose materials with enhanced mechanical properties to minimize the risk of product defects.

6. Challenge: Optimize Productivity and Cycle Time

Balancing injection speed, cycle time, and cooling time is paramount for maintaining production efficiency.

Solution

- Use simulation tools to help reduce cycle times and optimize cooling strategies without compromising the integrity of the part.

Dramco’s Advantage

Dramco Tool specializes in creating complex multi-shot die injection molds for the consumer and automotive industries. Our molds fit in presses of up to 1,300 tons in capacity and can produce parting lines that are consistent throughout long production runs. We work closely with our clients during the design phase to develop molds that are both cost-effective and durable.

For decades, we have also been building and designing compression molds for SMC and BMC-type materials. With a particular focus on multi-piece mandrels, we are experts in making Invar and aluminum layup molds and RTM molds. We can support your entire mold-building process, from bond fixtures to tooling carts to machine fixtures and more.

Dramco offers on site tooling support to ensure tools are ready for sampling and production with minimal down time with start ups.

At Dramco Tool, we embrace a customer-centric approach to manufacturing so that we meet your requirements throughout the design and build process. Request a quote to learn more about die injection molding and how our molds can meet the demands of your next project.